office (713) 849-3366

fax (713) 849-3654

toll-free (800) SAY-AAAT

Pipe Supports and Hangers

Pipe Supports

AAA Technology manufactures engineered spring hangers in accordance with the applicable ANSI/ASME Codes for Pressure Piping, MSS Standards SP-58 and SP-69 and the applicable U.S. Government specifications pipe supports. Quality is designed and built into every engineered "EQUAL™" and "EQUALBALANCE™" variable or constant spring hanger.

Pipe Designs

Specially designed and manufactured constant or vaiable units are available upon request. Installation and inspection procedures are available upon request.

|

EQUAL™ ENGINEERED

VARIABLE SPRING HANGERS

& VARIABLE BASE SUPPORTS EQUAL™ variable spring hangers are provided in seven canister types and four series to support loads ranging from 53 pounds (23.8 Kilograms) to 50,010 pounds (22,685 Kilograms). An inventory of assemble EQUAL™ variable spring hangers and rigid hanger components ready for assembly are maintained to enable AAA Technology to respond promptly to our customers' needs. Download Catalog in Pdf |

|

EQUALBALANCE™ ENGINEERED

CONSTANT SPRING HANGERSSpring Hangers"EQUALBANLANCE™' constant effort spring hangers are provided in the horizontal, vertical and up thrust canister types in range of sizes supporting loads from 19 pounds (8.6 Kilograms) to 98,866 pounds (44,846.5 Kilograms). EQUALBALANCE™ constant effort spring hangers are available in prime, shop or custom paint and hot dip galvanized finish.Download Catalog in Pdf |

|

HIGH LOAD BOX SPRINGS AAA Technology manufactures engineered spring hangers in accordance with the applicable ASME Codes for Pressure Piping, MSS Standards SP-58 and SP-69 and the applicable U.S. Government specifications. High Load box springs provide excellent stability where small vertical movement and high loading is expected and loads up to 250,000 can be accommodated. |

|

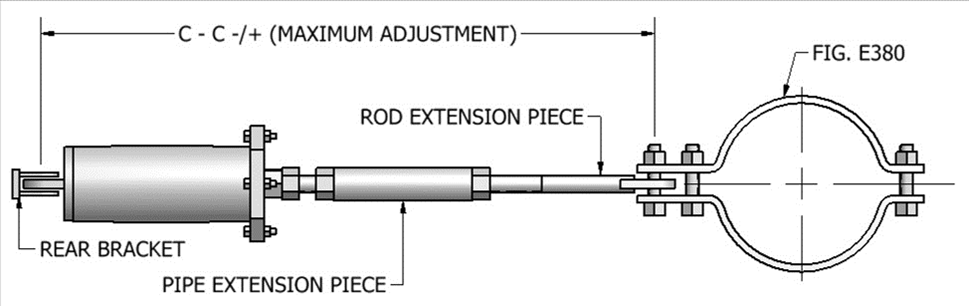

RIGID SWAY STRUT ASSEMBLIES AAA Technology inventories a stock of components for use in both the welded and the adjustable rigid sway strut units. Upon receipt of your requirements and order, we will assemble the necessary components and ship the rigid sway strut units you require. |

|

Sway Brace

Assemblies

AAA Technology

manufactures a standard line of sway brace assemblies

capable of handling loads up to 7,200 lbs. and pipe

diameters up to 42”.

AAA Technology maintains an inventory of components and can

produce finished assemblies quickly.

Sway Brace Assemblies can be designed and

manufactured for non-standard loads, movements and pipe

diameters. Sway Brace

Assemblies can be provided with Bracket End Connections

and/or special 3 Bolt Pipe Clamps and are available in the

following finishes: Carbon Steel – black, painted and hot

dip galvanized or Stainless Steel – plain |

|

Snubbers For absorbing thrust associated with the release of blow off valves which may cause immediate or accumulative damage to piping or equipment. For use with piping subjected to shock, sway or vibration caused by earthquake, water hammer, or other transient forces. |

|

VIBRATION CONTROL RESTRAINTS

FOR

PIPELINES AND BOTTLES Field proven and tested in years of numerous applications worldwide and can be designed to accommodate both Dynamic and Thermal flexibility requirements for temperature -65F (18C) to 350F (177C). Mechanical clamp stiffness's and bolt torque recommendations are available for each design to aid in installation. |

|

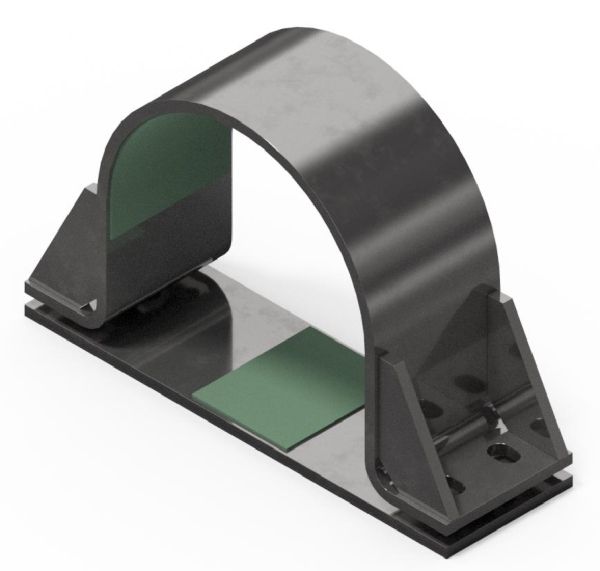

TRI*SLIDE™ LOW FRICTION

SLIDE PLATES The TRI*SLIDE™ low friction pipe supports are a family of pipe slide plate assemblies and pipe shoes offering a wide range of designs and attachment configurations from which to select. For hot piping systems, AAA Technology offers designs from the standard T-bar shoe to several reinforced shoe designs for welding to the pipe. For hot piping systems where welding to the pipe is not permitted, we offer several designs of u-bolted and clamped shoes. Several designs for welded and bolted guide units are also available. Variations of these designs, excluding the designs calling for welding to the pipe, are also offered for low temperature and cryogenic applications. TRI*SLIDE™ low friction pipe supports incorporate two mating bearing surfaces between the pipe and the support structure thereby permitting piping movements parallel to the bearing surfaces while offering relatively low resistance to movements. TRI*SLIDE™ units may be ordered with your choice of the following bearing surfaces: high quality graphite plates or industrial quality glass filled PTFE bonded to steel plates. TRI*Slide™ Brochure in PDF TRI*Slide™ High Temperature Brochure in PDF |

|

TRI*FOAM™ MOLDED RIGID POLYURETHANE PIPE SADDLES AND SUPPORTS The TRI*FOAM™ molded rigid polyurethane pipe saddles and supports are a family of pipe support and restraint units especially designed for low temperature and cryogenic service. A wide variety of designs are offered from the 60 degree wedge to the 180 degree saddle, and further to the 360 degree full encirclement unit. We also offer layered units for extreme service conditions. TRI*FOAM™ saddles are molded high quality, high density polyurethane units with a low “K” factor (thermal conductivity). When the units are subjected to temperatures in the range of -425 degrees F to plus 200 degrees F, TRI*FOAM™’s physical characteristics, including compressive strength, will not be significantly affected. AAA Technology’s TRI*FOAM™ molded rigid polyurethane pipe saddles and supports are available with vapor barriers and/or steel shields as well as in combination with the TRI*SLIDE™ low friction pipe supports. Specially designed and manufactured units are also available upon request. |

|

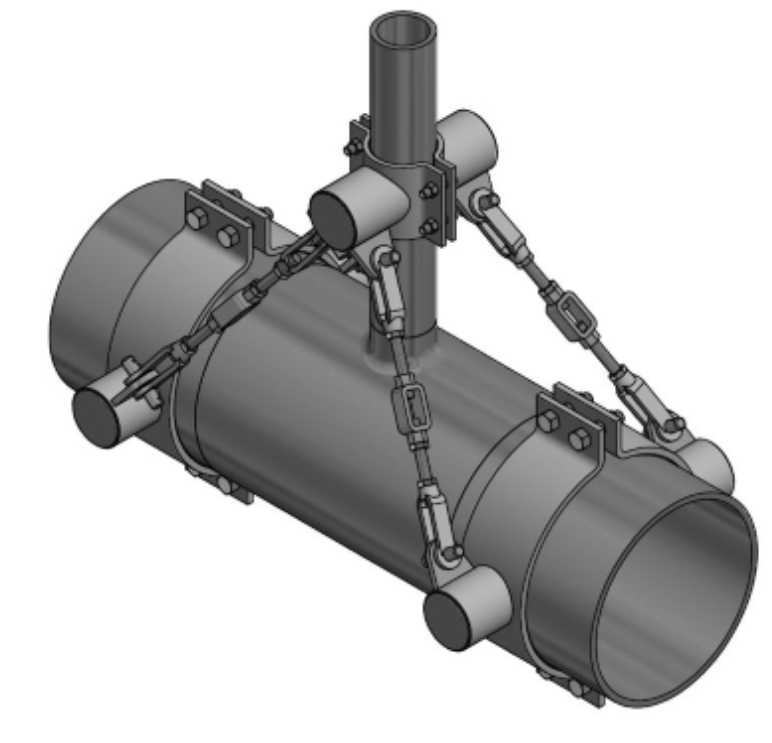

TRI*BRACE™ BRANCH LINE VIBRATION

SOLUTIONS TRI*BRACE™ has been develped to address the frequently encoutered issue of small branch lines vibrating and cracking at the connection to the header. It is common to see field fabricated arrangemnts generlly fabricated of angles and plates. The clamps utilized typically have a rubber liner and the bracing members are angles. When the attachment point is a flange, a plate is typically attached by placing a arc plate with the flange shape and with flange bolt pattern drilled in it. Failure typicaly occurs at he welded connection between the angles and the clamps or plates. |

|

TRI*WEAR™ Pads are pipe

protective coverings used to prevent corrosion and

electrical conductivity between the pipe and the pipe

support. They also prevent metal to metal abrasion &

dampen vibrations. TRI•WEAR™ acts as a second skin

reinforcing the contact surface. These pads are seal bonded

to the pipe in order to prevent moisture collection behind

the wear pads. Bonded TRI•WEAR pads provide up to 45,000 psi

compressive strength and work from -60⁰F to 500⁰F. They are

available in pipe sizes from ¾” to 36”.

Specially designed and manufactured units are also available upon request. |

|

TRI*COMPOSITE™ Pipe Shoes

-

These shoes are easy to install and greatly reduce the

“Installed Cost” per shoe. They can be epoxied to the

pipe or banded as shown. Made from high density

polyurethane foam cores (cut by numerical control equipment)

with a toughened FRP outer shell, the shoe has enhanced

thermal insulating properties while preventing electrical

conductivity and corrosion and can be used for pipes from

-350°F up to 225°F. Our TRI•COMPOSITE Pipe Supports

are available in light and heavy duty, strapped or bonded in

pipe diameters of ¾” to 36”. Specially designed and manufactured units are also available upon request. |

|

Pipe Support HardwareAAA Technology maintains a large stock of rigid hanger components, in both black and hot dip galvanized finishes, including rods (Machine Thread & All Thread), eye rods, weld less eye nuts, forged steel clevises, forged steel turnbuckles, two and three bolt pipe clamps, riser clamps, socket clamps, special clamps, pipe straps, clevis hangers, beam clamps, C-clamps, welded beam attachments, welding lugs, U-bolts, pipe rolls, pipe roll stands, pipe covering protection saddles, insulation protection shields, bolts, nuts, washers and horizontal travelers. Individual hanger components may be shipped in bulk or AAA Technology’s staff can assemble hangers as required and ship to your jobsite in a timely fashion |

| VIBRATION DAMPERS AND SWAY BRACES AAA Technology stocks components for use in both spring coil type and rotary friction type vibration control and sway brace units. Vibration control and/or sway brace units are shipped upon order requirements. |

|

|

MISCALLENOUS FABRICATION Adjustable Stands Instrument Stands U-Bolt Angle Stands Dummy Legs Phenolic Insulators Elastomeric Bearings Anchor Bolts & Sleeves |

|

CUSTOM FABRICATED PIPE SHOE For hot piping systems, AAA Technology offers designs from the standard T-bar shoe to several reinforced shoe designs for welding to the pipe. Where welding to the pipe is not permitted, we offer several designs of u-bolted and clamped shoes. |

|

ANCHOR BOLTS & SLEEVES - All thread studs,

double end studs, hook bolts, J-bolts, bent J-bolts & chemical

anchors...black, painted or galvanized. PHENOLIC INSULATORS - Beechwood Blocks, Permali Blocks, Micarta Blocks, Sleeves and Washers. INSTRUMENT STANDS - Single or Double Upright Instrument Stands built to your specifications. |

Elastomeric Bearings for

Vibration/Noise Reduction, Random Fiber Orientation Woven

Reinforced and PTFE coated and Neoprene. Anchor Bolts & Sleeves Brochure in PDF |

Corrosion Protection Products

Brochure Download

AAA Technology & Specialties Co., Inc. has the pleasure of introducing a line of Corrosion Protection Products that is specially designed to protect your pipe in severe environmental and marine conditions. Some of the following benefits are achieved:

- Stops induced electrical currents

- Eliminates localized galvanic corrosion

- Keeps humidity away from supports

- Provide a second skin of protection

- Variety of clamps, hangers and supports

- Products for cryogenic applications

- Products for restraint or slide bearing.

When used in marine conditions, exposure to salt water or spray makes this kind of

protection critical, because salt acts as an electrolyte to accelerate corrosion.

So this added protection is an insurance for continued service in these conditions or

where there is excessive humidity. Our conventional FRP products operate from -60°F

to 500°F, but our toughened epoxies can go as low as from -350°F .

Please call us or email

info@aaatech.com for further information.