office (713) 849-3366

fax (713) 849-3654

toll-free (800) SAY-AAAT

Spring Hanger Information

Variable Spring Hangers - When to use

Spring hangers should be used when:

When pipe at a support location moves up off a rigid support & when it is necessary for support loading to be maintained.

When pipe at a support location needs to move downward to relieve load on equipment or stresses in the piping system.

When loads on attached equipment nozzles are limited and a spring hanger would assist in controlling the nozzle loading.

In other words, spring hangers are used to carry the dead weight of the piping system at a given support while allowing movement resulting from thermal

expansion or contraction of the piping system. Spring hangers are frequently used at the first pipe support location adjacent to rotating equipment

such as turbines, compressors, pumps or expander-compressors. At these support locations, the amount of vertical piping movement is typically small.

However to enable the loading on the equipment to be controlled, a spring hanger is used to apply a support load on the pipe. In all instanced where

the use of spring hangers is contemplated, evaluate the alternatives considering factors such as loading on equipment, cost, ease of installation and

ease of operation. If spring hangers are the most economical and most satisfactorily solution, then by all means use them.

DESIGN FEATURES:

Hanger casings are made of pipe for long life and durability.

Spring coils are pre-compressed into the hanger casings reducing the overall casing length and insuring that support loads can be obtained by making only a small adjustment.

The finishes available for hanger casings are primed, painted or hot dipped galvanized. For extremely corrosive service conditions, SermaGard® coatings are offered.

These finish options provide our customers with a full range of choices.

Mechanically closed units allow AAA Technology to stock components from which hangers can be easily and quickly assembled for your hanger requirements.

Mechanically closed units allow AAA Technology to insure that all components are properly finished and that no welding is required after the finishes are applied.

SPECIFICATIONS:

AAA Technology's "EQUAL" brand variable spring supports are designed to meet the requirements of the Manufacturers Standardization Society's MSS SP-58

"Hangers and Supports—Selection and Application" as well as the ASME Codes for Pressure Piping. Spring hanger casings to be utilized in corrosive environments

are galvanized in accordance with ASTM Specification A-153 unless the customer opts for the SermaGard® coating.

Variable spring hangers - Determining size

Spring Hanger Types

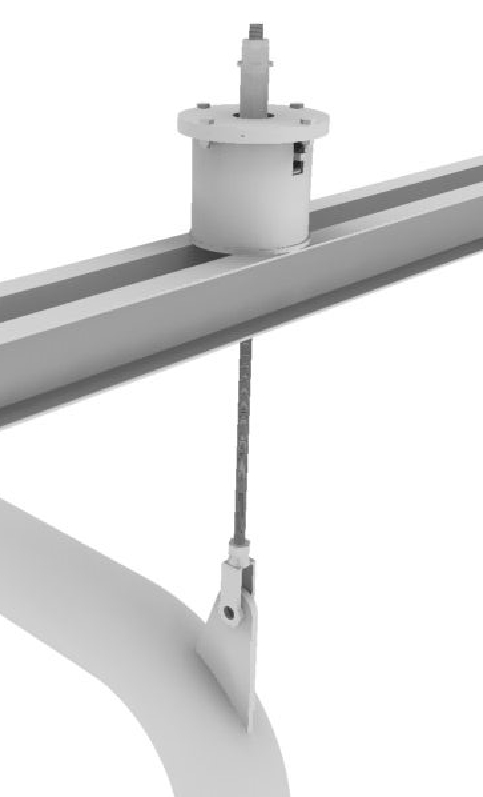

| Type A-Used where ample head room is available. Specific elevation is desirable. |

| Type B-Used where headroom is limited. Head attachment is a single lug. |

Type

C-Used where headroom is limited. Head attachment is

side by side lugs. Type

C-Used where headroom is limited. Head attachment is

side by side lugs. |

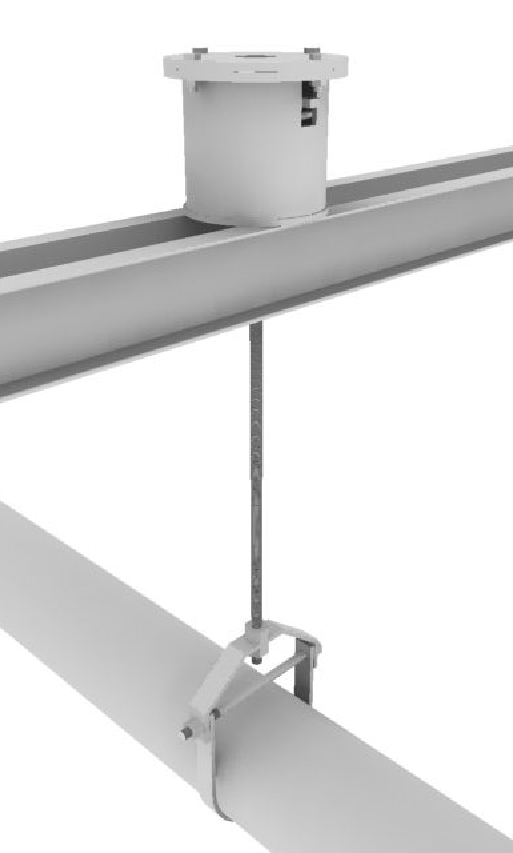

Type

D-Used where the spring hanger is mounted on top of a pair

of back to back channels. Provides for adjustment of

the load from above the supporting channels. Type

D-Used where the spring hanger is mounted on top of a pair

of back to back channels. Provides for adjustment of

the load from above the supporting channels. |

|

| Type E-Used where the spring hanger is mounted on top of a pair of back to back channels. Provides for adjustment of the load from below the supporting channels. |

|

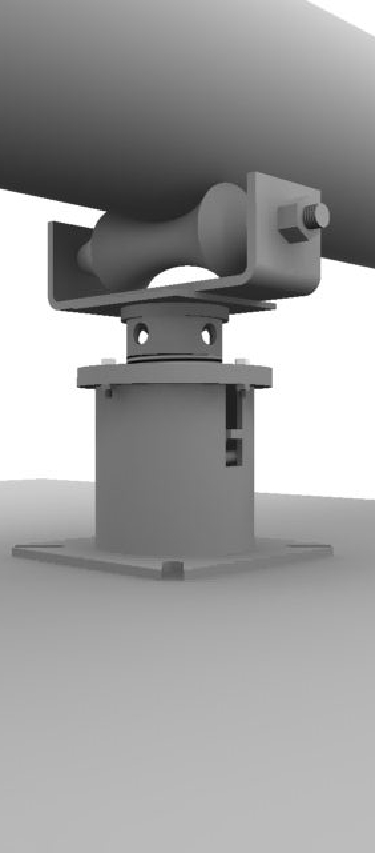

Type F-Used where the spring hanger must be placed under the piping to provide support from the floor or a structural member. Typically supplied with a load flange but can also be supplied with a roller. |

|

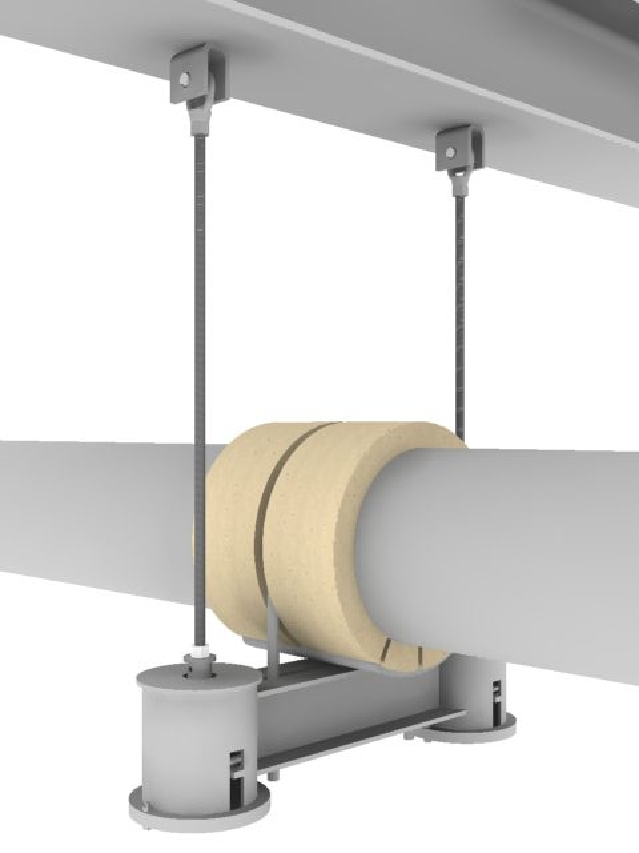

Type G-Used were head room is insufficient to accommodate the spring hanger and the necessary associated hardware. Also used where an interference exits directly above the piping system being supported is not centered between the spring hangers, each hanger will then carry its proportional load. |

Variable Spring Hanger Selection Chart

Series E82

|

|

|

|

|

Series E268

|

|

|

|

|

Series E98

|

|

|

|

|

Series E100

|

|

|

|

|

Series E110

|

|

|

|

|

Light Duty

| Single Spring Hanger | Double Spring Hanger |

| Single with HDG Finish | Double with HDG Finish |